Product Consultation

Your email address will not be published. Required fields are marked *

Choosing the Right Metal Shed Panels for Different Environmental Conditions: A Guide to Durable and Reliable Solutions

Apr 24,2025

Why Choosing High-Quality South Africa Tiles is the Smartest Decision for Your Next Project

Apr 17,2025

How Proper Roof Drainage Design Helps Prevent Costly Structural Damage in Steel Buildings

Apr 10,2025When it comes to blending functionality with aesthetics in modern architecture, few materials offer the versatility and reliability of metal shed panels. These innovative solutions are not just about utility—they’re about creating structures that stand out while standing strong. From customizable finishes to sustainable design trends, metal shed panels are redefining how architects and builders approach both residential and commercial projects. Let’s dive into why these panels are becoming a go-to choice for forward-thinking designs and how they can elevate your next project.

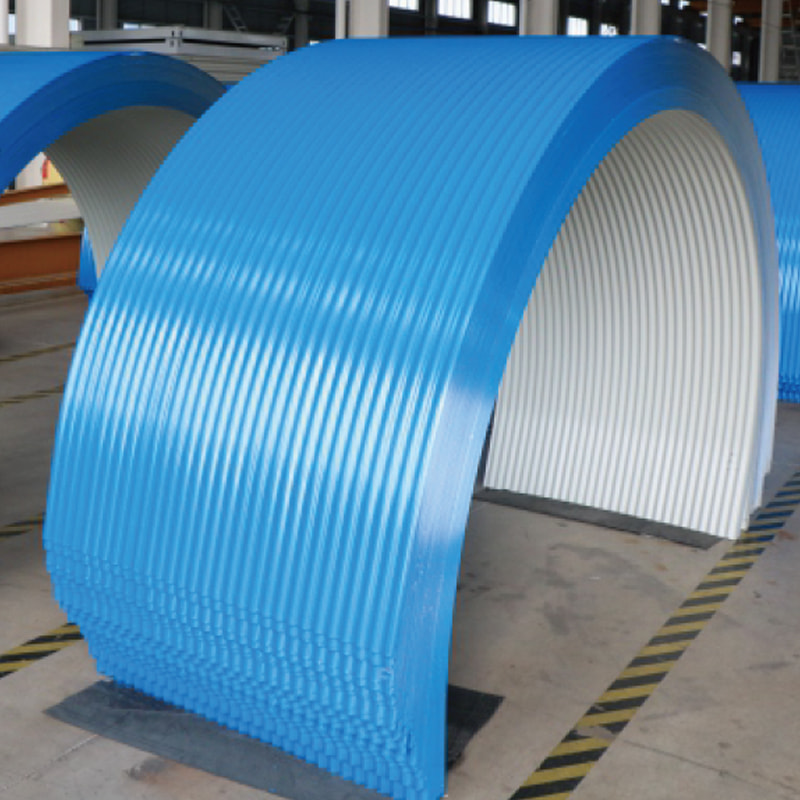

Customization is king in today’s architectural landscape, and metal shed panels are leading the charge. Imagine being able to tailor every aspect of your building’s exterior to match its surroundings or reflect a client’s unique vision. Whether it’s choosing from a spectrum of colors, experimenting with textures like matte or brushed finishes, or even incorporating curves that mimic natural landscapes, the possibilities are nearly endless. Computational design software has revolutionized this process, allowing manufacturers to create bespoke metal panel solutions that align perfectly with high-end architectural demands. For instance, crimp curved sheets can now be designed with precision to ensure seamless integration into complex rooflines, all while maintaining the structural integrity needed for long-term performance. This level of adaptability ensures that metal shed panels aren’t just functional—they’re transformative.

But aesthetics alone don’t cut it in modern construction; sustainability is equally critical. As green building certifications like LEED and BREEAM gain traction, architects are increasingly turning to eco-friendly materials, and metal panels fit the bill beautifully. One exciting trend is the integration of photovoltaic cells into roofing systems, transforming ordinary metal shed panels into energy-generating powerhouses. Reflective coatings are another innovation worth noting—these coatings reduce heat absorption, keeping interiors cooler and lowering energy costs. By opting for such sustainable design features, builders not only contribute to environmental conservation but also enhance the market value of their projects. After all, who wouldn’t want a structure that looks stunning, performs efficiently, and leaves a smaller carbon footprint?

Of course, no discussion about metal shed panels would be complete without addressing their role in industrial applications. Conveyor belt cover hoods and roof drain gutters, for example, showcase how these panels can be engineered for specialized purposes. In harsh environments, such as coastal areas prone to salt spray or industrial zones with heavy dust, durable steel edge bending parts provide an extra layer of protection. Meanwhile, customizable roof drain gutters ensure optimal water management, preventing costly damage from pooling rainwater or snowmelt. These practical applications highlight the versatility of metal shed panels, proving that they’re not just for show—they’re workhorses too.

From a manufacturing perspective, achieving such high levels of customization and durability requires cutting-edge techniques. Precision engineering plays a pivotal role here, ensuring that every metal shed panel meets exact specifications without compromising quality. Advanced coating technologies, such as nanocoatings and galvanization, further enhance the lifespan of these products, making them resistant to corrosion even in challenging climates. The result? Metal shed panels that are as resilient as they are beautiful, capable of withstanding years of wear and tear while maintaining their visual appeal.

In conclusion, whether you’re designing a sleek urban office, a rustic countryside home, or a robust industrial facility, metal shed panels offer unmatched potential. Their ability to combine style, sustainability, and strength makes them a standout choice for architects and builders alike. So, if you’re looking to push the boundaries of what’s possible in modern construction, consider integrating these versatile panels into your next project. After all, when it comes to crafting spaces that inspire, metal shed panels might just be the secret ingredient you’ve been searching for.

Maximizing Efficiency: Metal Shed Panels for Industrial Applications

Feb 24,2025

How Milano Stone Coated Steel Roof Tiles Excel in Earthquake-Prone Regions

Feb 13,2025Your email address will not be published. Required fields are marked *

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1280 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6.2kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 1.67pcs

Unit area weight: 7.2kgs/sqm

Tile size: 1700 * 420mm * 0.4mm

Installation size: 1640 * 370mm * 0.4mm

Thickness: 0.4mm

Tile size: 790 * Nmm * 0.4mm

Effective area: 700 * Nmm * 0.4mm

Lages color steel tiles have proficient techniques and precise CNC machine equipment for the production of edge finishing parts, equipped with 6-meter and 9-meter bending machines. Production and processing of various specifications and models of bending parts, including galvanized sheet bending parts, color steel sheet bending parts, stainless steel bending parts, aluminum sheet bending parts, black iron sheet bending parts, galvanized gutter sinks, steel plate laminating parts, etc.

Name: Color steel curved tile

Steel thickness: 0.5-0.8mm

Model: YX28-205-820/1025

Advantages and Characteristics:

High strength: The toughness and strength of steel plates are very high, which can withstand wind and heavy pressure without deformation or fracture.

Self-cleaning ability: The steel plate surface is treated with a special coating to ensure smooth drainage and prevent sewage accumulation, with a clean and beautiful appearance design. The appearance design of the steel arc-shaped tile is beautiful, which can make the building more fashionable and modern.

The use of roof drain pipes in conjunction with steel buildings can make steel buildings more integrated, simple and elegant. A variety of supporting accessories are provided to meet various installation requirements. Compared with ordinary PVC pipes, they have better high and low temperature resistance and weathering resistance.

Our roof drain pipes can be customized according to the specific structure and design requirements of the building, including parameters such as pipe diameter, pipe length, curvature, etc., which can be flexibly designed to fully adapt to the drainage needs of various irregular buildings and improve drainage efficiency.

If you are interested in our Metal Roofing Tiles, please consult us.

Address :Dagong Town, Haian County, Nantong City, Jiangsu Province of China

Tel/WhatsApp: +86-15265997346

Email: [email protected]