Product Consultation

Your email address will not be published. Required fields are marked *

Choosing the Right Metal Shed Panels for Different Environmental Conditions: A Guide to Durable and Reliable Solutions

Apr 24,2025

Why Choosing High-Quality South Africa Tiles is the Smartest Decision for Your Next Project

Apr 17,2025

How Proper Roof Drainage Design Helps Prevent Costly Structural Damage in Steel Buildings

Apr 10,2025When it comes to selecting metal shed panels for your building project, one of the most important considerations is the environmental conditions the panels will face. The right choice of metal panels can significantly impact the durability, efficiency, and overall performance of your structure. Understanding how different environmental factors—such as extreme weather, humidity, and exposure to corrosive elements—affect your building can guide you in choosing the best materials for long-lasting results. By selecting high-quality metal shed panels that are tailored to your project’s unique requirements, you can ensure that your structure withstands the test of time and the elements.

In areas with extreme temperatures, such as freezing winters or scorching summers, the performance of your metal shed panels is crucial. High-quality panels designed to handle these shifts in temperature will prevent warping, cracking, or rusting that could compromise the integrity of your building. Panels that are properly insulated also help in maintaining a comfortable indoor environment by minimizing heat loss in the winter and reducing heat buildup in the summer. This not only improves the energy efficiency of the building but also saves on long-term operational costs. Choosing the right metal panels designed to combat these temperature fluctuations can keep your building protected year-round.

Humidity is another critical factor that affects metal shed panels, especially in regions with high moisture levels or near bodies of water. Without proper protective coatings or corrosion-resistant features, exposure to moisture can cause metal panels to degrade over time. To combat this, look for metal panels with advanced corrosion-resistant treatments. These panels are engineered to withstand rust and corrosion, ensuring they maintain their structural integrity and aesthetic appeal for decades. By selecting high-quality, moisture-resistant metal shed panels, you can protect your building from the damaging effects of humidity and prevent costly repairs.

For buildings located in coastal regions or areas with saltwater exposure, the risk of corrosion is even greater. Saltwater can accelerate the degradation of metal surfaces, leading to rust, pitting, and structural failure. Choosing metal shed panels that are specifically designed for coastal environments—such as those with additional protective coatings or made from high-quality materials like galvanized steel—can help to mitigate these issues. These specialized panels offer enhanced protection against saltwater corrosion, ensuring your building remains safe, secure, and visually appealing despite harsh coastal conditions.

Wind and storm-prone areas present another challenge for metal shed panels. High winds can exert significant pressure on a building’s outer surfaces, potentially causing damage to weaker panels or causing them to dislodge entirely. When selecting metal shed panels for buildings in these areas, it’s essential to choose products that are engineered for wind resistance. These panels are designed to withstand heavy gusts without compromising the safety of the structure. Additionally, proper installation techniques play a role in ensuring the panels stay secure during storms and adverse weather conditions, offering peace of mind to building owners.

Another consideration when selecting metal shed panels is their environmental sustainability. Many metal panel manufacturers now offer environmentally friendly options that reduce the environmental impact of your building project. Panels made from recyclable materials or designed to be energy-efficient can help to lower your building’s carbon footprint. By opting for eco-friendly metal shed panels, you not only contribute to environmental sustainability but also enjoy the benefits of energy savings and reduced waste over time.

In conclusion, selecting the right metal shed panels for your project requires a careful evaluation of the environmental conditions the structure will face. By considering factors like temperature extremes, humidity, corrosion risks, and weather conditions, you can choose metal panels that are specifically engineered to meet your needs. With a wide range of options available, from corrosion-resistant coatings to wind-resistant designs, the perfect metal panels are out there for every application. By investing in durable, high-quality panels, you’ll ensure that your building remains strong, secure, and efficient for many years to come. Don't settle for anything less than the best when it comes to metal shed panels—choose a solution that stands up to the elements and adds lasting value to your property.

No previous article

Jan 01,1970

Why Choosing High-Quality South Africa Tiles is the Smartest Decision for Your Next Project

Apr 17,2025Your email address will not be published. Required fields are marked *

Thickness: 0.4mm

Coverage area: 2.4pcs

Unit area weight: 5.9kgs/sqm

Tile size: 1280 * 420mm * 0.4mm

Installation size: 1220 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6.2kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 0.455pcs

Unit area weight: 2.8kgs/sqm

Tile size: 730 * 740mm * 0.4mm

Installation size: 650 * 700mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1280 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 2.8kgs/sqm

Tile size: 600 * 740mm * 0.4mm

Installation size: 540 * 680mm * 0.4mm

Thickness: 0.4mm

Tile size: 790 * Nmm * 0.4mm

Effective area: 700 * Nmm * 0.4mm

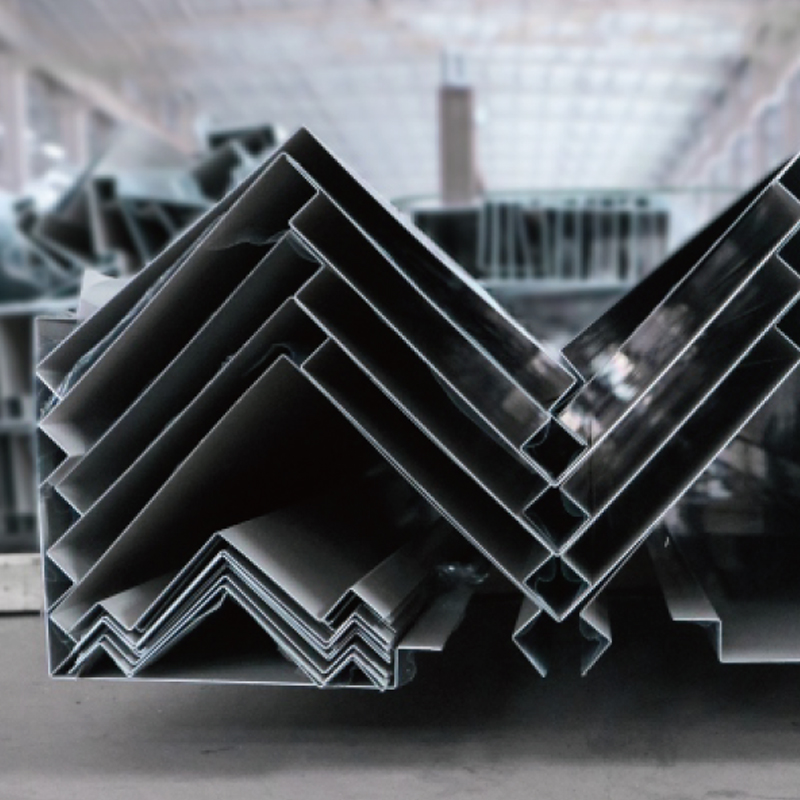

Lages color steel tiles have proficient techniques and precise CNC machine equipment for the production of edge finishing parts, equipped with 6-meter and 9-meter bending machines. Production and processing of various specifications and models of bending parts, including galvanized sheet bending parts, color steel sheet bending parts, stainless steel bending parts, aluminum sheet bending parts, black iron sheet bending parts, galvanized gutter sinks, steel plate laminating parts, etc.

If you are interested in our Metal Roofing Tiles, please consult us.

Address :Dagong Town, Haian County, Nantong City, Jiangsu Province of China

Tel/WhatsApp: +86-15265997346

Email: [email protected]