Product Consultation

Your email address will not be published. Required fields are marked *

Maximizing Roof Longevity and Protection with Stone-Coated Steel Roofing Tiles: Why Galvanized Steel Matters

Apr 02,2025

Maintenance and Longevity of Metal Shed Panels: How to Keep Your Building Strong and Functional

Mar 24,2025

Maximizing Durability and Design with Metal Shed Panels: Engineering and Customization Explained

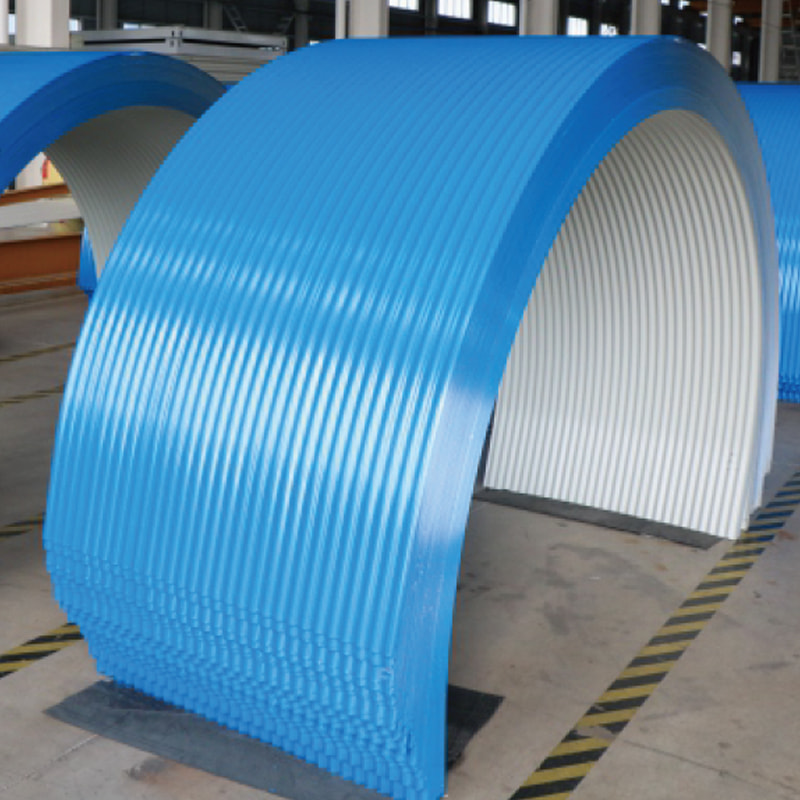

Mar 21,2025One particularly interesting case is a large-scale agricultural facility that required a building design that could withstand extreme weather conditions while also accommodating specialized equipment. This project had several unique features, such as a curved roof structure to facilitate water runoff and custom steel edge bending parts to match the building’s non-traditional shape. The panels were used in both the walls and the roof, and their durability was put to the test in an area prone to heavy snowfalls and high winds. The crimp curved sheets were instrumental in ensuring proper drainage, while the steel edge bending parts were customized to follow the gentle curve of the roof, all without compromising structural integrity. This project not only met the aesthetic vision of the architects but also stood strong against the elements, ensuring long-term durability and protection.

Another example comes from the manufacturing sector, where LAGOS' metal shed panels were used to construct a large warehouse designed to house a complex conveyor system. The client needed robust protection for the machinery, as well as a durable, weather-resistant structure to house the system. The conveyor belt cover hoods were a perfect fit, offering the required weather protection while maintaining operational efficiency. The steel edge bending parts were tailored to suit the unique shape of the warehouse, ensuring a clean finish at all the building’s edges, while the customizable roof drain gutters provided an essential drainage solution for the sloped roof. The result was a highly functional space that supported the smooth operation of the client’s machinery, even in challenging environmental conditions.

In yet another project, our metal shed panels were used in a logistics hub for a global supply chain company. Here, the panels needed to accommodate the installation of extensive conveyor systems and provide long-lasting weather protection. The adaptability of the metal shed panels allowed for seamless integration with the existing systems. The steel edge bending parts were custom-fitted to match the design and configuration of the warehouse, while the crimp curved sheets ensured water runoff was effectively managed across the expansive roof. The project was completed on schedule and exceeded expectations in terms of both durability and aesthetic appeal.

These examples show how LAGOS’ metal shed panels have been successfully implemented in a variety of industries, meeting both practical and aesthetic needs. From agricultural facilities requiring resistance to harsh weather, to manufacturing warehouses housing intricate machinery, our panels have demonstrated their ability to adapt to the unique requirements of diverse projects. The key to these successes lies in our willingness to work closely with clients to customize the panels to fit the specific needs of each project. Whether it’s customizing the steel edge bending parts or designing an effective drainage system, LAGOS provides tailored solutions that ensure both functionality and visual appeal. These case studies not only demonstrate the flexibility of our product but also the reliability and long-term value they offer for complex, specialized applications.

Stone-Coated Steel Roof Tiles: Ideal for Heavy Snow and Seismic Areas

Feb 06,2025

Can Steel Edge Bending Parts Be Custom-Fit for Unique Structures?

Jan 25,2025Your email address will not be published. Required fields are marked *

Thickness: 0.4mm

Coverage area: 2.4pcs

Unit area weight: 5.9kgs/sqm

Tile size: 1280 * 420mm * 0.4mm

Installation size: 1220 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1280 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1280 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 2.8kgs/sqm

Tile size: 600 * 740mm * 0.4mm

Installation size: 540 * 680mm * 0.4mm

Thickness: 0.4mm

Tile size: 790 * Nmm * 0.4mm

Effective area: 700 * Nmm * 0.4mm

Lages color steel tiles have proficient techniques and precise CNC machine equipment for the production of edge finishing parts, equipped with 6-meter and 9-meter bending machines. Production and processing of various specifications and models of bending parts, including galvanized sheet bending parts, color steel sheet bending parts, stainless steel bending parts, aluminum sheet bending parts, black iron sheet bending parts, galvanized gutter sinks, steel plate laminating parts, etc.

Name: Color steel curved tile

Steel thickness: 0.5-0.8mm

Model: YX28-205-820/1025

Advantages and Characteristics:

High strength: The toughness and strength of steel plates are very high, which can withstand wind and heavy pressure without deformation or fracture.

Self-cleaning ability: The steel plate surface is treated with a special coating to ensure smooth drainage and prevent sewage accumulation, with a clean and beautiful appearance design. The appearance design of the steel arc-shaped tile is beautiful, which can make the building more fashionable and modern.

The use of roof drain pipes in conjunction with steel buildings can make steel buildings more integrated, simple and elegant. A variety of supporting accessories are provided to meet various installation requirements. Compared with ordinary PVC pipes, they have better high and low temperature resistance and weathering resistance.

Our roof drain pipes can be customized according to the specific structure and design requirements of the building, including parameters such as pipe diameter, pipe length, curvature, etc., which can be flexibly designed to fully adapt to the drainage needs of various irregular buildings and improve drainage efficiency.

If you are interested in our Metal Roofing Tiles, please consult us.

Address :Dagong Town, Haian County, Nantong City, Jiangsu Province of China

Tel/WhatsApp: +86-15265997346

Email: [email protected]