Product Consultation

Your email address will not be published. Required fields are marked *

Maximizing Roof Longevity and Protection with Stone-Coated Steel Roofing Tiles: Why Galvanized Steel Matters

Apr 02,2025

Maintenance and Longevity of Metal Shed Panels: How to Keep Your Building Strong and Functional

Mar 24,2025

Maximizing Durability and Design with Metal Shed Panels: Engineering and Customization Explained

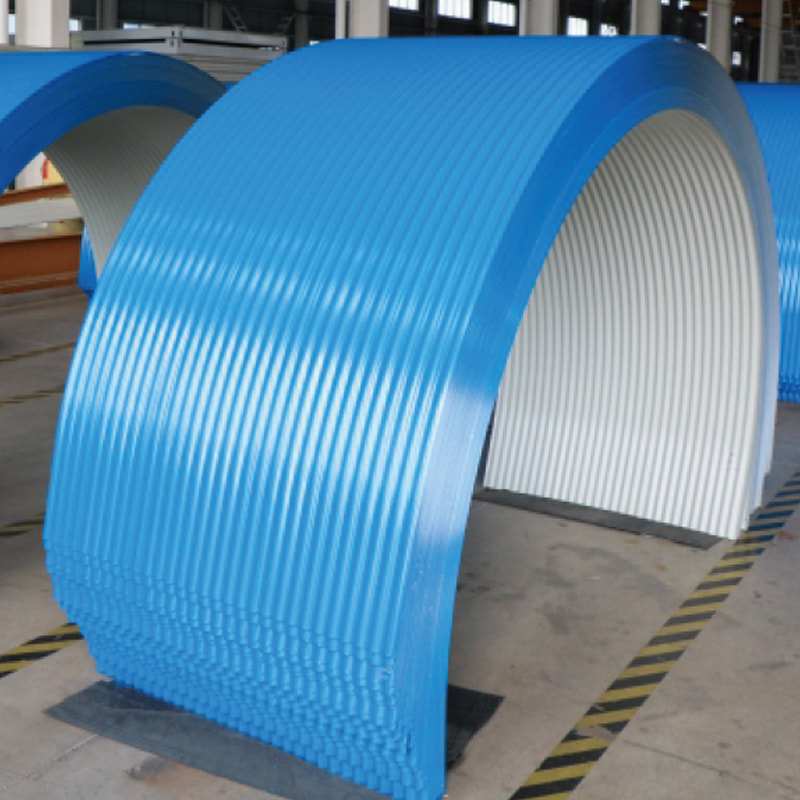

Mar 21,2025In the world of material handling, ensuring that a conveyor system runs smoothly is key to maintaining operational efficiency and minimizing downtime. One often overlooked component that plays a significant role in achieving this is the rainproof cover. While seemingly simple, these covers have a profound effect on the overall efficiency of a conveyor system, especially in terms of maintenance and long-term operation. When made from durable materials like colored steel with thicknesses ranging from 0.45 to 0.8mm, these covers do more than just protect the belt from rain—they are an essential part of the conveyor system that prevents potential disruptions and enhances productivity.

The primary function of the Colored Steel Conveyor Belt Rainproof Covers is to protect the system from external environmental factors like rain, snow, and dust, which can be major culprits in reducing the longevity and efficiency of conveyor belts. Without these covers, the belts are left exposed to the elements, leading to accelerated wear and tear, the accumulation of debris, and even material contamination. This not only increases the risk of conveyor failure but also heightens maintenance needs, as regular cleaning and repairs become a constant necessity. By shielding the conveyor from the elements, these covers significantly reduce the frequency of maintenance required, ensuring that the system remains operational for longer periods, and minimizing the need for costly repairs and part replacements.

From a maintenance perspective, these rainproof covers save both time and money. Maintenance teams can focus on preventive measures and minor adjustments instead of dealing with the fallout of major system failures caused by external damage. The corrosion resistance of these covers is especially valuable in environments where exposure to water or other corrosive elements is high. Since the covers are designed to endure harsh weather, they offer long-lasting protection that keeps the internal components of the conveyor system in pristine condition, avoiding rust, cracks, and degradation of the belt, pulleys, and other critical components. Additionally, the covers’ bright colors not only provide aesthetic value but also make it easier to spot any wear or damage early, ensuring that small issues don’t escalate into costly problems.

The flexibility and ease of installation of these covers also contribute significantly to their efficiency in terms of operation. Unlike other protective systems that may require complex setups or adjustments, the rainproof covers can be installed quickly and with minimal disruption to the workflow. This ease of installation means that even if a conveyor needs to be relocated or modified, the covers can be adapted without much hassle, ensuring that the system continues to operate efficiently. Furthermore, because these covers are designed with user-friendliness in mind, they can be easily replaced if damaged, without requiring the entire conveyor system to be taken offline for extended periods.

In terms of overall operation, the rainproof covers directly contribute to the consistency of the conveyor system’s performance. By preventing external factors like rain or dust from interfering with the materials being transported, the covers ensure that there are fewer disruptions caused by material contamination or product damage. For industries dealing with sensitive goods or materials that must remain dry or free from debris, such as pharmaceuticals or food production, this level of protection is crucial. In these settings, having a protected conveyor system means that operations run smoothly without the added stress of dealing with water damage or contamination, leading to increased throughput and higher productivity.

The Colored Steel Conveyor Belt Rainproof Covers are not just a cosmetic addition to a conveyor system—they are a practical investment that enhances the system's longevity, efficiency, and reliability. By reducing maintenance needs, protecting against wear and tear, and ensuring smooth, uninterrupted operations, these covers allow businesses to maintain high productivity levels and reduce downtime. With the added benefits of corrosion resistance, easy installation, and a sleek, bright appearance, they are an essential component for any company looking to improve their conveyor system’s performance and keep their operations running efficiently.

How Slate Stone-Coated Steel Roof Tiles Stand Up to Temperature Changes

Dec 06,2024

Bond Colored Stone Coated Metal Roof Tiles: Wind Resistance & Durability Explained

Nov 19,2024Your email address will not be published. Required fields are marked *

Thickness: 0.4mm

Coverage area: 2.4pcs

Unit area weight: 5.9kgs/sqm

Tile size: 1280 * 420mm * 0.4mm

Installation size: 1220 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1280 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 6.2kgs/sqm

Tile size: 1300 * 420mm * 0.4mm

Installation size: 1250 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 0.62pcs

Unit area weight: 3.2kgs/sqm

Tile size: 860 * 830mm * 0.4mm

Installation size: 830 * 770mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 11pcs

Tile size: 600 * 210mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.1pcs

Unit area weight: 6kgs/sqm

Tile size: 1340 * 420mm * 0.4mm

Installation size: 1290 * 370mm * 0.4mm

Thickness: 0.4mm

Coverage area: 2.3pcs

Unit area weight: 2.8kgs/sqm

Tile size: 600 * 740mm * 0.4mm

Installation size: 540 * 680mm * 0.4mm

Thickness: 0.4mm

Tile size: 790 * Nmm * 0.4mm

Effective area: 700 * Nmm * 0.4mm

Lages color steel tiles have proficient techniques and precise CNC machine equipment for the production of edge finishing parts, equipped with 6-meter and 9-meter bending machines. Production and processing of various specifications and models of bending parts, including galvanized sheet bending parts, color steel sheet bending parts, stainless steel bending parts, aluminum sheet bending parts, black iron sheet bending parts, galvanized gutter sinks, steel plate laminating parts, etc.

Name: Color steel curved tile

Steel thickness: 0.5-0.8mm

Model: YX28-205-820/1025

Advantages and Characteristics:

High strength: The toughness and strength of steel plates are very high, which can withstand wind and heavy pressure without deformation or fracture.

Self-cleaning ability: The steel plate surface is treated with a special coating to ensure smooth drainage and prevent sewage accumulation, with a clean and beautiful appearance design. The appearance design of the steel arc-shaped tile is beautiful, which can make the building more fashionable and modern.

If you are interested in our Metal Roofing Tiles, please consult us.

Address :Dagong Town, Haian County, Nantong City, Jiangsu Province of China

Tel/WhatsApp: +86-15265997346

Email: [email protected]